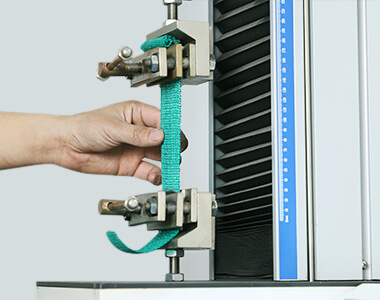

Strict Supervision Results in Quality Nets

We are well aware of the importance of the quality management during production and followed by action.

A worker is assigned to each knitting machine to observe the weaving process so that machine failures and quality issues can be timely addressed. Our workshop directors will also inspect every 1 hour to detect production errors.